- Page d'accueil

- Imprimantes 3D et accessoires

- Modelage

- Moulage & Tirage

- Tin Silicones

- Platinum Silicone

- La série Dragon Skin™

- la série Ecoflex ™

- Série Equinox ™

- La série Mold Star ™

- La série Rebound ™

- La série Smooth-Sil ™

- la série SORTA-Clear™

- La série Body Double™ - Silicones pour la peau

- Psycho Paint™

- Platsil Gels- Deadener- Hardener & Retarder

- Rubber Glass

- Encapso™ K

- Solaris ™

- Soma Foama™ - Mousse de silicone

- EZ-Brush ™ Vac Bag Silicone

- EZ-Spray silicones platines

- Silicone Additives

- PU - Élastomères

- Alginate

- PU - Résines

- FormCast Rhino

- FormCast Burro

- Crystal Clear ™ serie

- Plasti-Paste™

- Smooth-cast 45D / 60D / 61D / 65D / 66D

- La série Smooth-Cast™ 300

- La série Smooth-Cast™ 325 EU,326 EU & 327 EU

- La résine Smooth-Cast™ 385

- Smooth-Cast™ ONYX™

- Feather Lite™

- La série Task™

- Shell Shock™

- SMASH! Plastic™

- EZ-Spray Plastique Uréthane

- Axsson

- PU - Mousses

- Epoxy

- Polyester

- Plâtres et béton

- Latex & mousses de latex

- Mask Making Latex

- Mold Making Latex

- FormX Elastica

- Monster Makers Mousse de latex

- Monstermakers Mask making latex RD-407

- Monstermakers additives & Components

- Holden's HX-200™ Coating/Dipping Latex

- Holden's - Body Latex™ - Brossable

- Holden's Mold Making Latex HX-80™

- Holden's HX-974™ Brossable - fabrication de moule

- Holden's Mask Making Latex - Pourable HX-407™

- Holden's Mask Making Latex - Brushable HX-807™

- Holden's Cosmetic Latex™

- Holden's HX-Frisket Masking Latex™

- Holden's HX-Injection Medium™

- les accessoires Latex

- Latex Pigments

- Latex Paint

- Latex Thickener

- AcrylCast polymère

- Prince August

- Jesmonite Systeme Acrylique

- Buddy Rhodes Système en Béton

- Pigments

- Jesmonite Pigments

- Pure Pigments

- Ultra Fine Pigments

- Silc Pig - Pigments pour silicone

- Glow Worm - Pigments phosphorescents

- Cryptolyte-additif UV luminescent

- Silicone Pigments - Electric

- SilTone

- SilTone Kits

- Fuse-FX peinture Silicone

- Silicone Coloring System S.A.M

- Key Pigments pour Silicone

- Kryolan Fibre Flock

- Latex Pigments

- Polyester Pigment

- UVO Pigments - Colorants résistants aux UV

- SO-Strong - Pigments pour polyuréthanes

- Ignite - Pigments fluorescents

- Real Metal Powders

- Cast Magic ™ Powders

- Faux Metal Powders

- Peintures

- Maker Pro Paint™

- Maker Pro Paint™ Fluorescent

- Maker Pro Paint™ Metallics

- Maker Pro Paint Additive

- Vallejo - Peintures acryliques

- Vallejo - couleurs métalliques

- Vallejo - boue acrylique

- Vallejo Primers and Laquer

- Psycho Paint™

- Latex

- latex - Base de peinture

- Fuse-FX peinture Silicone - Serie LY

- Fuse-FX peinture Silicone - Serie F

- Fuse-FX peinture Silicone - Serie M

- Jesmonite peinture

- Les charges & Finitions

- Les Solvants & Les Diluants

- Agents d'étanchéité & les démoulants

- Additifs

- Adhésif

- Outillage

- Outils FormX

- Airbrush System

- Pinceaux jetable

- Protections

- mesurer, peser et mélanger

- Protection du corps

- Outils à enduits

- Prince August

- Head Armatures

- Pinceaux Maquillage

- Éponges et Applicateurs

- SILI-CUP

- Estampilles et moules

- Tools For Concrete

- Sanding Tools

- Hair punching tools

- Aluminium Pail Opener

- Équipement

- Maquillage

- Cannom PM RMGP Colors

- Skin Illustrator palettes

- Skin Illustrator liquide

- FleshTone 60ml

- FleshTone 120ml

- Dark FleshTone 60ml

- Dark FleshTone 120ml

- FX 60ml

- FX 120ml

- FX 240ml

- Complexion 60ml

- Complexion 120ml

- Alchemy 60ml

- Alchemy 120ml

- Grunge 60ml

- Grunge 120ml

- Grunge 240ml

- Mardi Gras 60ml

- Mardi Gras 120ml

- Necromania 60ml

- Mekash Colors 60ml

- Clear Gloss 60ml & 120ml

- Glo-Worm 60ml & 120ml

- Tattoo Classic 60ml & 120ml

- Sunburn

- Alphabetical all

- Skin Illustrator Singles

- Skin Illustrator Glazing Gels

- Skin Illustrator Glazing Spray

- Skin Illustrator Concentrates

- MaqPro Bruise Gel

- Skin Illustrator Mouth FX

- Allied FX (Blue Bird)

- RipperFX Palettes

- Old Age Stipple (Marques de vieillesse)

- Stacolor Palettes

- Pax Thomas Suprenant (Peintures)

- Tattoo Sheets

- MaqPro Farde Palettes

- Pinceaux Maquillage

- MaqPro Make-Up Mixer

- MaqPro Creamy

- Estampilles et moules

- Sponges and Applicators

- Head Armatures

- FormX Tools

- Kryolan Make-Up

- Effets spéciaux

- matériel prothétique

- Guide

- Marques

- FormX Academy

- Literature

Élastomère polyuréthane brossable

Achetez Smooth-On chez FormX

Smooth-On est l'un des principaux fabricants mondiaux de matériaux de modélisation 3D tels que les matériaux de fabrication de moules, de coulée et d'effets spéciaux, mais aussi les résines de coulée industrielles, les adhésifs et les équipements. FormX est le principal distributeur des produits Smooth-On en Europe.

Brush-On 35

Les Brush-On sont des élastomères polyuréthanes pour des applications au pinceau (ou spatule) en plusieurs couches successives.

Très polyvalents, les Brush-On sont connus pour leur très grande résistance à l'abrasion, à la déchirure et pour leur retrait négligeable.

Apprécié pour sa facilité d'utilisation (mélange 1:1), la série Brush-On répondra parfaitement aux demandes de prises d'empreintes verticales, tout en capturant les moindres détails de vos modèles d'origine.

Idéal pour les reproductions d'objets (sculptures, bas-reliefs,...) la restauration architecturale (murs, plafonds, corniches,...), la fabrication de moules-chaussettes, l´élastomères BRUSH-ON 35 est parfaitement adapté aux tirages de béton et autres matériaux abrasifs. Facile à mélanger et à appliquer avec un pinceau ou une spatule, BRUSH-ON 35 s'applique sur les surfaces verticales et durcit avec un retrait négligeable pour donner un caoutchouc durable qui fonctionne en production. Parmi les applications courantes de BRUSH-ON 35 figurent les moules de restauration architecturale sur site, la reproduction de sculptures (moules à la cire d’art bronze - procédé à la cire perdue) et la fabrication d’effets spéciaux.

Il est possible de réduire le shore (dureté) avec l'ajout de So-Flex.

Dureté Shore: 35 A

Résistance à la traction: 10 N / mm

Durée de vie en pot: 20 min

Temps avant durcissement: 16 heures

Fiche technique séries Brush-On

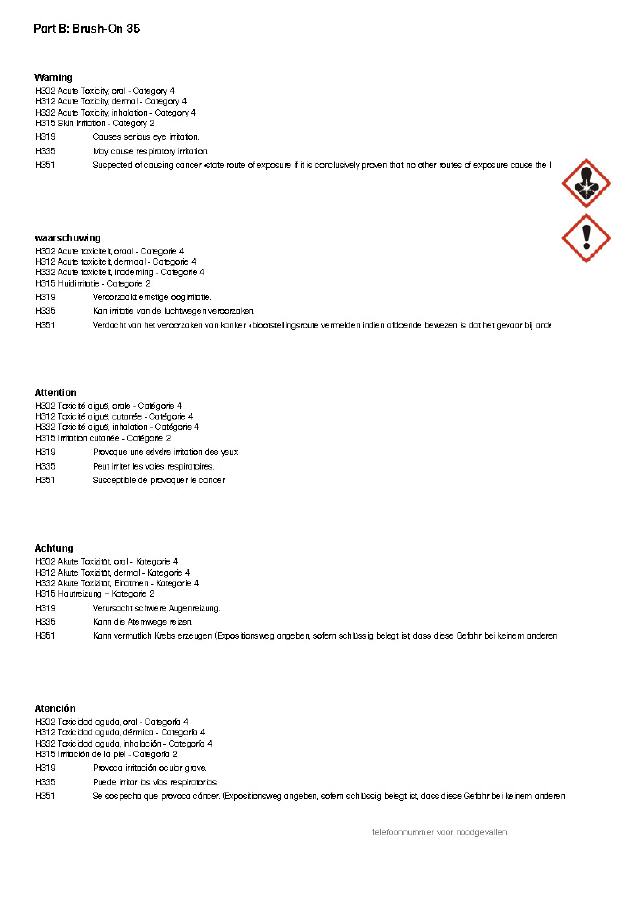

Safety Brush-On part B

- Lisez les informations de sécurité cliquez sur l'image

- Lea la etiqueta de información de seguridad. Haga clic en la imagen

- Lees het veiligheidsinformatie label. Klik op de afbeelding.

- Lesen Sie das Sicherheitsinformationsetikett. Klicken Sie auf das Bild.

- Read the safety information label. Click on the image

Produits Brush-On

Faire un moule composé souple/dur

Brush-On 35 peut très bien être utilisé en combinaison avec Plasti-Paste pour créer un moule composé avec un intérieur souple et un extérieur dur. Un tel moule est réalisé en appliquant la Plasti-Paste sur le moule Brush-On sans l'aide d'un agent de démoulage. Les deux matériaux d'uréthane vont maintenant être liés ensemble pour faire une couche de composé solide. Un tel moule est très approprié pour les grandes pièces moulées, par exemple béton.

Brush-On 35 peut très bien être utilisé en association avec Plasti-Paste pour créer un moule composite avec un intérieur flexible et un extérieur dur. Un tel moule est réalisé en appliquant la plasti-pâte sur le moule Brush-On sans utiliser d'agent de démoulage. Les deux matériaux d'uréthane vont maintenant se lier pour former une couche composite solide. De tels moules sont très bien adaptés aux gros moulages, par exemple. béton.

Preparation - Materials should be stored and used in at room 23°C. Humidity should be low. These products have a limited shelf life and should be used as soon as possible. Wear safety glasses, long sleeves and rubber gloves to minimize contamination risk. Good ventilation (room size) is necessary.

Some Materials Must Be Sealed - To prevent adhesion between the rubber and model surface, models made of porous materials (gypsum plasters, concrete, wood, stone, etc.) must be sealed prior to applying a release agent. SuperSeal™ or One Step™ available from form X are fast drying sealers suitable for sealing porous surfaces without interfering with surface detail. Shellac is suitable for rough contours. A high quality spray shellac is suitable for sealing modeling clays that contain sulfur or moisture (water based). Thermoplastics (polystyrene) must also be sealed with shellac or PVA.

In all cases, the sealing agent should be applied and allowed to completely dry prior to applying a release agent.

Non-Porous Surfaces - Metal, glass, hard plastics, sulfur free clays, etc. require only a release agent.

Applying A Release Agent - A release agent is necessary to facilitate demolding when casting into or over most surfaces. Use a release agent made specifically for mold making (Universal™ Mold Release available from form x). A liberal coat of release agent should be applied onto all surfaces that will contact the rubber.

IMPORTANT: To ensure thorough coverage, lightly brush the release agent with a soft brush over all surfaces of the model. Follow with a light mist coating and let dry for 30 minutes. Because no two applications are quite the same, a small test application to determine suitability for your project is recommended if performance of this material is in question.

IMPORTANT: Shelf life of product is reduced after opening. Remaining product should be used as soon as possible. Immediately replacing the lids on both containers after dispensing product will help prolong the shelf life of the unused product. XTEND-IT™ Dry Gas Blanket (available from Smooth-On) will significantly prolong the shelf life of unused liquid urethane products.

MEASURING & MIXING - Liquid urethanes are moisture sensitive and will absorb atmospheric moisture. Mixing tools and containers should be clean and made of metal, glass or plastic. Materials should be stored and used in a warm environment 23°C.

Mixing - Part A is a paste with the consistency of cake frosting. Fill a container to the top with this paste, making sure to eliminate any large voids. Level off the top of the container and remove any excess material. The paste should then be thoroughly emptied into a larger container that will act as your mixing container. Next, fill the original container to the top with Part B (liquid) and empty it into the mixing container. After dispensing equal amounts of Parts A and B into mixing container, mix thoroughly for 3 minutes making sure that you scrape the sides and bottom of the mixing container several times.

Applying The Rubber - This product must be applied in layers. Mold makers generally find that four to six layers (minimum 3/8”) thickness is suitable for a working mold. Using a stiff brush, the first coat of rubber should be applied in a thin layer to capture intricate detail. Use dabbing strokes, especially around undercuts, to reduce entrapped air. Subsequent coats will add strength to the mold. Let the first coat dry for 30-40 minutes at room temperature or when it becomes “tacky” before adding the next coat. Repeat until the necessary thickness is achieved. Do not allow rubber to fully cure between layers, as delamination may result. Note: Although not necessary, adding a small amount of SO-Strong™ liquid color pigment available at form X to every other mix of rubber will help you distinguish one layer from the next. This will ensure that you apply a thorough coating each time and help build uniform layers.

Curing - Allow rubber to cure overnight (at least 16 hours) at room temperature 23°C before demolding. Cure time can be reduced with mild heat or by adding Smooth-On “Kick-It™” Cure Accelerator. Do not cure rubber where temperature is less than 18°C.

Post Curing - After rubber has cured at room temperature, heating the rubber to 65°C for 4 to 8 hours will increase physical properties and performance.

Apply A Support Shell - Once the mold is fully cured, a rigid support shell (mother mold) is needed to support the rubber mold during casting. Plasti-Paste™ II is a trowelable plastic which is ideal as a mother mold material.

Using The Mold - If using as a mold material, a release agent should be applied to the mold before each casting. The type of release agent to use depends on the material being cast. The proper release agent for wax, liquid rubber or thermosetting materials (i.e. Smooth-On liquid plastics) is a spray release made specifically for mold making (available from Smooth-On or your distributor). Prior to casting gypsum plaster materials, sponge the mold with a soap solution for better plaster flow and easy release. In & Out™ II Water Based Release Concentrate available from form x is recommended for releasing abrasive materials like concrete.

Performance & Storage - Fully cured molds are tough, durable and will perform if properly used and stored. The physical life of the mold depends on how you use it (materials cast, frequency, etc.). Before storing, the mold should be cleaned with a soap solution and wiped fully dry. Two part (or more) molds should be assembled. Molds should be stored on a level surface in a cool, dry environment. Do not stack molds, expose them to moisture or UV light.

Seaux, gobelets gradués et balances de pesée

pinceaux plats jetables

Masques, filtres et gants latex et vinyle.

Agents de démoulage

Naviguer par application ..

Ces produits sont classés par application telles que, le moulage du corps humain, le moulage, les tirages, les produits transparents, la restoration, le prototypage, etc...